Quality Management (QM) allows project teams to embrace construction quality as a collaborative, team effort and mindset. Departments have often been siloed, with Preconstruction focused on estimating/budgets, Operations focused on contracts/submittals, and Production focused on schedule/logistics. Adding Quality Management to the mix as an overarching team member provides continuity from start to finish—connecting each focus together seamlessly. Collectively, Krusinski Construction Company relies on teamwork and collaboration to extend our impact on the project with tighter budgets, reasonable schedules, realistic logistics, constructable detailing, material compatibility, code compliance and reduced risk.

Understanding the key tools and processes behind Quality Management is essential for elevating construction standards and empowering teams to deliver exceptional projects. These tasks below help our QM Team identify opportunities to improve the building experience:

- Drawing Review (uncover coordination/compatibility/sequencing issues)

- Code Analysis (uncover life-safety/fire-safety/exiting issues)

- Quality Planning (brings the team together to collaborate on constraints)

- Option Driven RFI (resolve constructability/warranty/coordination issues)

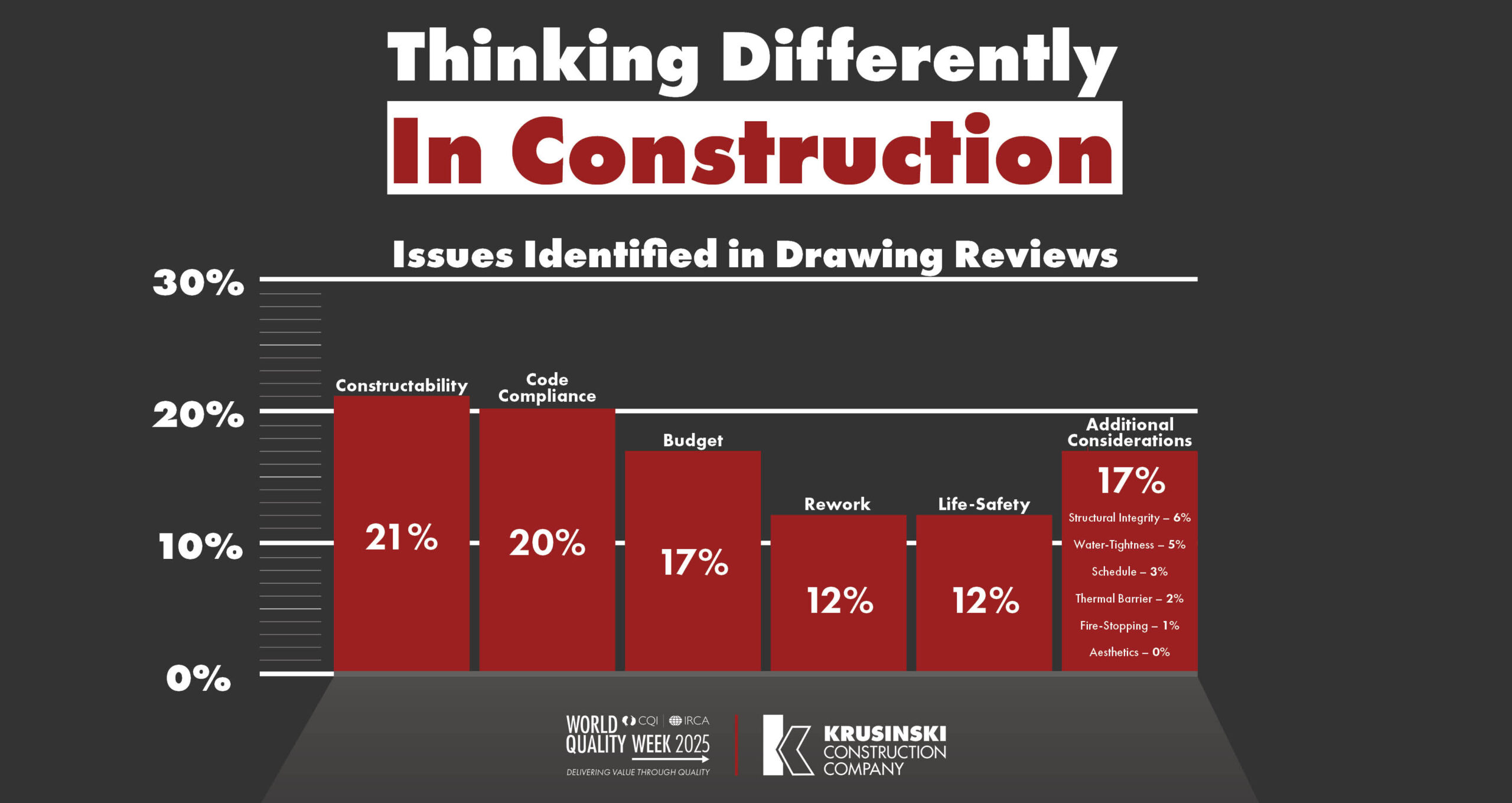

Drawing Reviews are a critical tool in our QM Process, allowing us to pre-emptively uncover items to be further honed. We understand the design intent/user needs and consider them as we undertake reviews. Those reviews are shared with the Project Team and become part of the proactive guide for estimating, contracting and construction.

Having licensed professionals on our team gives us the confidence to undertake Code Analysis, when necessary, to fully understand the needs of the project. We want to do our part to ensure our projects are fully compliant with accessibility, life-safety and fire-protection requirements.

Quality Planning brings our teams together to balance all aspects, knowing the ultimate solution considers them all. We work to improve the understanding of the design intent, occupant needs, municipality requirements and client desires to provide a more complete project. The goal is to be proactive in lieu of reactive, addressing issues prior to construction. This approach refines the budget, solidifies contracts, enhances the schedule and clarifies logistics.

Along with our suppliers and trade partners, we develop Option Driven RFIs for the concerns uncovered in our reviews and planning stage. We find that providing thoughtful options assures constructability and warrantability of the work to be installed and speeds up the approval process.

Consistently tracking Drawing Reviews over the last four years, KCC has averaged roughly 39+ comments per review. Among these comments, we are confident some saved last-minute RFIs and others avoided rework, which both would have impacted the schedule and budget.

It is often assumed that Quality Management only adds WORK to a project, when in fact, early identification of quality issues often minimizes the scope of work. As an example, drawings indicated to convert an un-rated wall to a fire-rated wall—requiring work above the client’s 24/7 control room. That work was a non-starter for the client, and they were not allowing any work completed to disrupt the control room. Our code analysis revealed that the fire-rating was not a code requirement, which was confirmed by the AOR/AHJ, determined that the unnecessary scope of work was eliminated.

Another assumption is that Quality Management adds COST to a project, when in fact, early identification of quality issues often reduces costs. As an example, drawings indicated for 5-70’ glue-laminated timbers be added to an existing roof to support rooftop mechanical units. After our discussion with trade partners and the project superintendent, it was revealed that moving those rooftop mechanical units 10’ from their proposed locations eliminated the need for glue-laminated timbers—at a savings of $150,000.

Our entire Quality Management Process impacts our Lessons Learned, and the knowledge collected at the end of every project, overall improves each of our current and future projects. Items in our Lessons Learned Library capture the Solution incorporated into the project, as well as suggestions for Moving Forward. A Lessons Learned might not be “the way we’ve always done it”, but we incorporate an improved method “moving forward”. With Quality Management involved in every project, we improve our ability to create consistency company-wide and utilize the best methods on all projects.

An Article Written by: Steve Beck, Quality Control Manager at Krusinski Construction Company